LEARN ABOUT OUR CUSTOMER HAPPINESS IMPROVEMENT PROGRAM

Delivery Performance

100%

On Time Delivery

1/3

of all ORDERS DELIVERED EARLY

<5

AVG. lEAD TIME FOR AS6081 testing (days)

4.5 out of 5

customer satisfaction

Join us for an industry panel discussion sponsored by SMTA Space Coast Chapter on March 21.

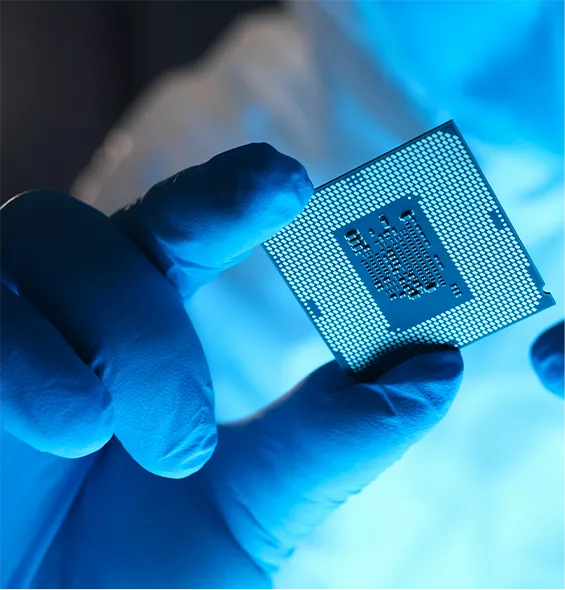

Ensure Reliability and Eliminate Risk

When working with vital electronic components for your organization’s highest priority needs, a counterfeit or substandard part could bring a stop to your operations. We provide quick-turn, extensive testing so you can rest assured that your electronic components conform to component specifications.

Services

Electrical testing

Passive Component Qualification, Pin Correlation, Memory Tests, JTAG and Boundary Scan Testing, AC/DC Parameters, DDR/DRAM Testing, Speed Verification, Up Screening & Functional Testing

Environmental testing

Humidity & Bias (THB) Test, Highly Accelerated Stress Test (HAST), Thermal Shock, & Burn-In

Component Authentication

External Visual Inspection, Solderability, Internal Visual Inspection, X-Ray, X-Ray Fluorescence (XRF), Scanning Electron Microscope (SEM) & Energy-Dispersive X-Ray Spectroscopy (EDX)

Additional Testing

Mechanical testing, chemical testing, failure analysis, PCB Design and Construction, Project Management, & Electrical Test Design and Setup

Watch our company video now

Industries We Serve

Military & Defense

Aerospace

Medical

Industrial

Automotive

Testimonials

GCI has been working with AAA Test Lab support for some unusual requests, with activity to create duplicates of obsolete integrated circuits. This includes detailed test program development. AAA Test Lab has become very responsive after resolving the scope of work requested. Very good communication between supplier and customer.

Patrick Jenkis

Program Manager - GCI

Quick responses for quotations, meets TAT commitment and provides professional test reporting.

Mike England

VP Quality & Logistics -

Sourceability North America

Overall Excellent Service + Excellent paperwork like C of C and Shipping documents.

Chirag Diyora

AIA Technologies Inc.

Great service, and appreciate the partnership!

Jake McAloose

Sales Manager

Astute Electronics, Inc.